Sheet Metal Fabrication

home / capabilities / sheet metal fabrication

From Concept to Scale

Cadrex is the foremost sheet metal manufacturer in North America, offering custom sheet metal fabrication services at strategically located facilities in the United States and Mexico. We provide our customers with the speed to scale required to quickly introduce new products into the market.

We have decades of experience designing and building sheet metal parts, sheet metal assembly, and integrated products for Fortune 500 companies. Our team of experienced engineers, designers, and manufacturers becomes an extension of our customers. We are with you from start to finish — from sheet metal prototyping and new product introduction (NPI) into production, to mechanical assembly, integration, and testing. Cadrex will work with you to create custom sheet metal fabrication solutions to your most complex challenges.

Metal Fabrication Capabilities

- Sheet Metal Engineering & Prototype Center

Design for manufacturability (DFM) is the process of designing products so they are easy to manufacture, and design for excellence (DFX) is the process of designing products to match high-quality, low-cost standards. Our sheet metal engineering experts are well-versed in DFM and DFX, and they consider these processes when designing a prototype. Sheet metal prototyping happens before manufacturing begins. Every product is evaluated and tested during the prototype phase to ensure a smooth and speedy production process.

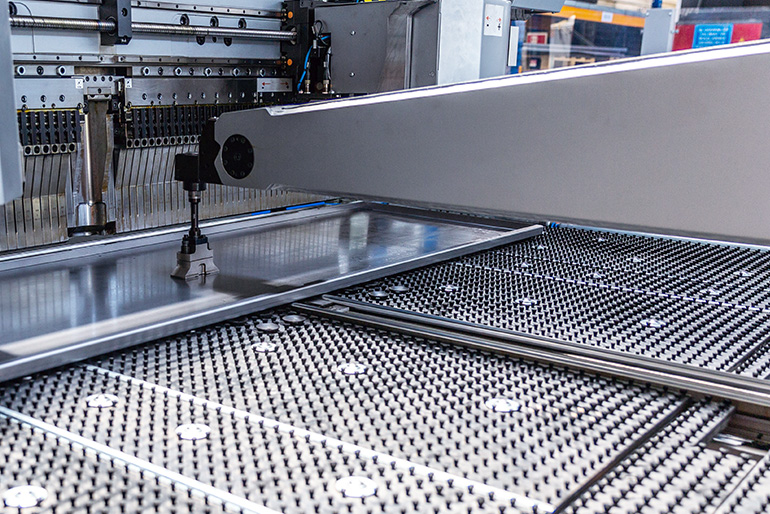

- Sheet Metal Fabrication – Cutting, Punching, & Bending

Sheet metal fabrication is the process of transforming a thin sheet of metal into a final product, and common methods include cutting, punching, and bending. Cutting is the use of blades, torches, or lasers to remove pieces of sheet metal. Laser cutting metal offers geometrical flexibility because the cut options aren’t limited to a standard tool. Punching is a metal forming process that uses a machine called a punch press to pierce or punch holes into the metal. Metal bending involves applying pressure to specific areas of the sheet metal and bending it to predefined specifications.

- Sheet Metal Stamping Presses from 30 to 300 Tons

Sheet metal stamping is the process of turning sheet metal into specific shapes. During the manufacturing process, sheet metal is fed into a press brake where it is shaped by a tool and die. The tonnage, or amount of pressure applied by the press, needed is determined by the type of metal and the desired shape. Metal stamping, also called hard tooling, is great for producing multiple, uniform metal parts at scale.

- Robotic Operators, Brakes, & Panel Bending

At Cadrex, we believe integrating automation and robotics into the manufacturing process equates to high-quality, efficient solutions. Our state-of-the-art equipment includes fully automated panel bender lines, stamping press lines, and CNC sheet metal machining centers. Robotic operators perform with uniform precision on repeat and can be quickly reprogrammed to accommodate last-minute engineering changes.

- Automatic Tool Changing & Loading/Unloading

Our automatic tool changing and material loading and unloading systems make setup easier and faster, and they make production continue seamlessly. When more than one tool is used, an automated tool changer (ATC) adds speed and accuracy to the manufacturing process. Once it receives its command, an ATC will remove an old tool from a CNC sheet metal machine and replace it with a new one. Many of our presses are also equipped with automated sheet loading and unloading systems, offering increased productivity by negating the need to manually load sheet metal onto the press.

- Mechanical Assembly & Hardware Insertion

Sheet metal assembly is another aspect of sheet metal fabrication; this method involves putting together individual parts to build a complete product. There are various types of mechanical assembly processes, typically determined by the product’s end use. Metal welding involves melting or soldering pieces of metal together. Riveting is the process of fastening pieces of metal together.

- Secondary Machining

When you work with Cadrex, you tap into a vast network of manufacturing services and capabilities. We are committed to ensuring your product reaches its full potential, and often that involves secondary machining beyond custom sheet metal fabrication. If metal manufacturing is the primary process, our precision machining capabilities can complete the project or take it to another level.

- Mig, Tig, and Robotic Welding

We perform all necessary forms of welding, including the most common: MIG, TIG, and robotic welding. Metal inert gas (MIG) creates an electric arc between a piece of wire and the metal it’s touching, causing them both to melt and join. Tungsten inert gas (TIG) is commonly used to weld thin pieces of stainless steel or aluminum, and it produces stronger welds than MIG welding. Robotic welding is a fully automated method to creating welded sheet metal. It is programmed by expert welders, and it is ideal for creating higher volumes.

- In-House Sheet Metal Tooling Design & Build

From design to delivery, everything can be done in-house at Cadrex. Our sheet metal design experts analyze critical dimensions and standard tolerances to develop a prototype and move your project through the production process. We determine the best tools for each project, and we can build, repair, and modify tools ourselves. We truly are a one-stop shop.

- Conveyor Paint Line, Pad Printing, & Silk Screening

Cadrex offers a myriad of mechanical assembly and finishing solutions, including conveyor paint line systems, pad printing, and silk screening. Products move through a conveyor paint line for finishing applications, like coat paint, powder coating, or wet spray. Pad printing is the process of transferring a 2-D image onto a 3-D object or part. Silk screening is a method of transferring ink or dye onto a base material or fabric around a stencil.

A Critical Component

Metal Fabrication Automation

Cadrex continues to invest in state-of-the-art sheet metal manufacturing equipment and automation to increase efficiency and quality. Robotic operations reduce safety risks and ergonomic hazards by eliminating the need for a human operator to make repetitive movements. Depending on your program size and requirements, our automation engineers will determine if robotic operators for sheet metal assemblies and integrations will benefit your program.

How Sheet Metal Fab Works

Sheet metal fabrication is the process of transforming thin sheets of metal into specific shapes. Metal fabrication uses laser cutters, turrets, press brakes, and panel benders to form parts and components through cutting, punching, and bending. Sheet metal fabrication, or metal forming, allows for a high amount of flexibility during a product's design, prototype, and production ramp. With zero to minimal tooling investments, products can quickly move from prototyping to production.

Uses of Sheet Metal Fabrication

The results of sheet metal fabrication are everywhere. The sheet metal industry is interwoven with other industries like aerospace, engineering, automotive, and construction. Sheet metal fabrication is used to create a wide array of products, including electrical storage units, gaming kiosks, cabinets, electric vehicle charging stations, and aerospace components.

Common Sheet Metal Materials

Aluminum

Aluminum 3003, Aluminum 5052, Aluminum 6061

Copper Alloy

Copper C110, Brass, Phosphorus Bronze

Stainless Steel

301, 302, 303, 304, 316, 400 series

CRS/HRS

.015"-.250" thickness draw quality to grade 50

Precoated

Pre-plate galvanized G30-G90, Galvanneal, Electrogalvanized, Aluminized, Pre-painted

Sheet Metal Fabrication Design Guide

Learn more about the metal fabrication and stamping process including terms, definitions, and industry best practices.

Related Links

Blog

Should Your Sheet Metal Manufacturing Partner Be Tech-Savvy?

There’s no shortage of reasons for manufacturers to embrace automated sheet metal production and other forms of advanced manufacturing technology...

White Paper

Sheet Metal Fabrication Starter Guide

Whether you’re liking a photo on social media or making the switch to a solar powered home, sheet metal is everywhere. And because its uses are so varied...

Blog

What To Look For When Sourcing Large Sheet Metal Enclosures

Sheet metal enclosures come in all shapes and sizes. It’s the larger ones, however, that often cause designers and manufacturers the most grief...